Our buyers guide to Laminate Doors and Panels

Made from a melamine resin coating that overlays a photographic image ...

Most of us are familiar with the basic features of Decorative Laminate Board; with this having reasonably high resistance to wear, heat and to staining, so here we would like to talk more about this versatile material in a little more detail and hope that this helps you with your selection process of finding the right material to suit your needs.

Laminate Kitchen Doors are made from Factory Laminated Board, these can have a core of either a Particleboard or an MDF (Medium-Density Fiberboard) or an HDF (High-Density Fiberboard) or even some with a Plywood core and all come in either Standard or Moisture Resistant versions. These boards are made into Laminated Board by pressing a series of films onto their surfaces, both sides; first using a Decorative photographic layer of either a Colour or a Woodgrain or a Pattern which is then followed by pressing a thin layer of hard-wearing, protective, clear melamine resin over the top.

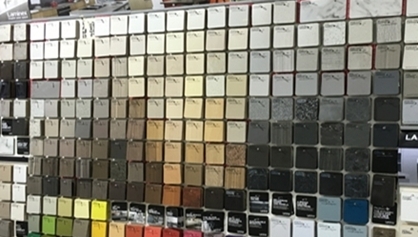

This Laminated board material is then cut by us to the sizes required to make Laminate Kitchen Doors and Panels, Open Shelving and Base Kickers. This Laminated board material is available in a huge selection of Colours, Patterns, Woodgrains and Metallics which are also pressed with plates making a wide variety of surface finishes too, these include; Matte, Ultramatt, Satin, Sheen, Textured, AbsoluteMatt, Natural, Flint, Grained, silk, semi-gloss and Gloss finishes.

Laminate Doors and Panels, in general, are Flat Two Dimensional panels so have limitations to the door design itself but lending itself well to the modern contemporary style. An exception to this is the Laminate Door called the Avellino which are shown at the bottom of this page which are made by cutting laminate board into rails and gluing these back to Laminate panels.

All types of Laminate door & Panels are cut to size from large sheets of Laminated Board and then need to have edge strips applied to their raw cut edges. Edges are generally finished with a matching colour edge strip (though these can be contrasting). The Edge Strip material types range from an inconspicuous 0.5 mm melamine strip, or a 0.5 - 1.0 mm printed PVC Edge Strip or a 1 mm and 2 mm in ABS plastic strip. Most Australian Laminate Board manufacturers today, however, have moved toward only making edge strip in the 1 mm and 2 mm in ABS plastic material to match their colour range. ABS is a lower density, printed strip, in a solid colour, where the edge and the joint line of these ABS Strips are quite visible. All these edge strip types produce a Square Edge profile around the door with a visible glue joint, which importantly is also susceptible to moisture penetration as well as colour fading and discolouration over time.

In addition to the differences in the type of core material to the board, there are also basically three variations of the type of Laminate coating used on board at the moment. Two types are made from a Melamine Resin coating as said above and one type uses a pressed Acrylic Coating. The Melamine is available in various finishes including; Matte, Satin, Textured, Grained and a Silk Gloss finish which has a slight ripple in the gloss surface. The alternative Acrylic laminated board is a dearer product which is mainly made with a superior High Gloss Finish, with some manufacturers also making an Acrylic Matte finish but in a limited colour range. The Acrylic Board is also cut and made into doors but can be Laser edge striped with edge strip made of the same type of Acrylic material as the face; where the advantage here is a far less visible joint line as the two pieces of Acrylic are fused together. The third type of Laminated Board on the market is also a Melamine Board which has an additional clear Matte coating pressed over the Melamine layer; where this special technology produces a Matte fingerprint-resistant finish. This Matte Finger Print Resistant Laminated Board is also cut into doors and needs to be Edgestripped in the usual manner. This Matte Finger Print Resistant Board and the Acrylic Laminated Board are also a lot dearer than standard Melamine Laminated Board.

While using Laminated Doors does have a clear cost advantage when compared to other types of door materials, there are however three main downsides to consider to all these Laminated Board materials. The first is that you are limited to the style and design of your door and therefore you are limited to the style of kitchen. Generally, Laminated Doors don't have three-dimensional decorative detail, like for example a Shaker Style door or Raised Panel Door. (It is possible to route Laminate door fronts to create a more decorative panel and paint the routed areas but this style has fallen out of favour today). The second downside is that these edge strips (especially the thicker ABS) have a visible edge and visible Joint line around each panel where these do become more obvious as time goes on, as the glue line and the edge strip discolours. The third downside to this type of material is that the join between the Laminate board and the Edge strip is again vulnerable to water penetration if it is not dried immediately and therefore making Laminated Doors susceptible to water damage over time. Laminate panels around dishwashers, around Kitchen Sinks, above Cooktops, around kettles, as well as general wet areas like the Laundry, Bathrooms or the Outdoors where there is exposure to water, steam or condensation are particularly vulnerable.

Here in Adelaide at Compass Kitchens we only use either Medium-Density Fiberboard core (MDF) or a High-Density Fiberboard Core (HDF) Laminate face boards for our Laminate Doors, End Panels and Kickers and we do not use the cheaper chipboard / Particleboard core Laminate panels even though these cheaper boards are available in all the same colours and patterns. We also only ever use the Highly Moisture Resistant (HMR) types of MDF and HDF boards, whereby providing an added layer of protection and a longer life span to these Laminated Doors and Panels; whereby providing you the best performance possible when you choose to use Laminated Face Board materials for your Kitchen and Cabinetry Doors and face Panels. It is also worth noting that Moisture Resistant does not mean Water Proof.

Reasonably new to the market is a Laminate Door product called Avellino, which is made to custom sizes for the trade by Polytec, who use some of their Woodgrain Laminate Board range to make these composite doors. This Avellino Laminate Door is made up of Two Side Rails with Vertical running Grain which are fixed to a Centre Panel with Horizontal running Grain that is then Edge stripped all around. The Avellino door is a stylish new alternative to having a plain flat Laminate Door and lends itself well when used in contemporary Scandinavian Style Kitchens.

For help in finding your favourite Kitchen Door Laminate Colour, Patern or Woodgrain you can find samples by visiting our Suppliers links we have set up for you at the bottom of our main Materials Page. Each Manufacturer also has the provision for you to order Free Laminate Colour Swatches which they will then post out to you. This is particularly helpful because you can not only see the true colour but also see the finish and get an idea of its performance.

Let's discuss your project

Compass Kitchens

Specializing in Kitchen Renovations here in South Australia we service all suburbs ranging from the Inner Adelaide districts and radiating out to the Eastern, Western and Southern suburbs and those extending throughout the Adelaide Hills and Fleurieu Peninsula including Goolwa to Victor Harbor to Normanville & Yankalilla.

Come home to a beautiful functional new kitchen renovation by Compass Kitchens.

Trading Hours :

Monday - Friday : 08h00 - 17h30

Saturday: 08h00 - 12h00, Sunday off work